Imagining The World of Nature

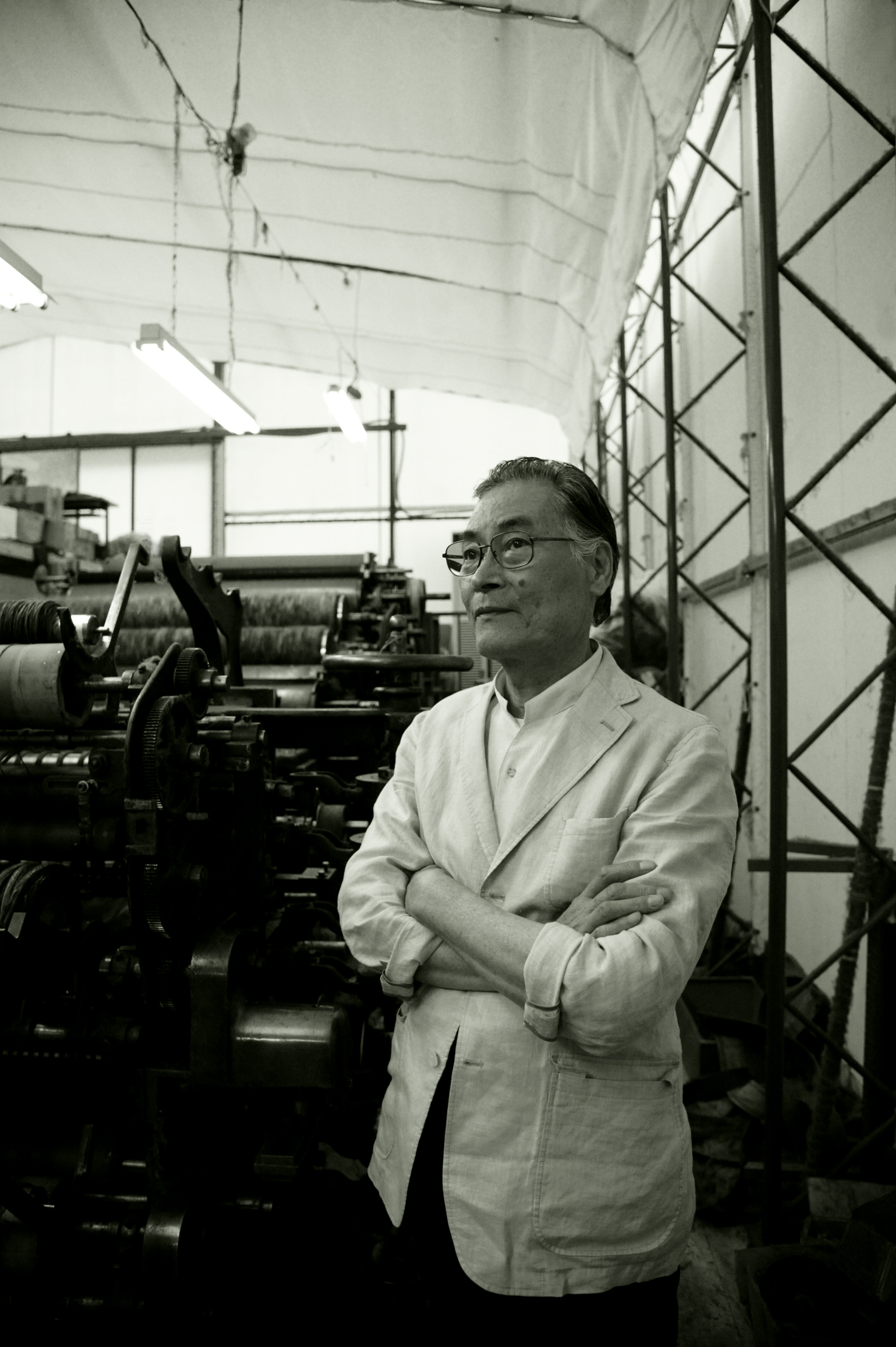

Noro — The World of Nature. Long before most companies had mission statements, Noro Yarn's founder, Eisaku Noro, chose those words to capture his vision.

"I was born and grew up in a place where more great unspoiled nature is left than anywhere else in Japan, so the world of nature is always close. Whether I am aware of it or not, I am inspired by it in many ways,"explains Noro.

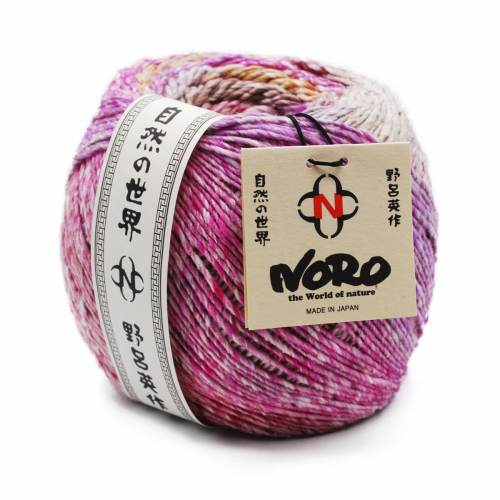

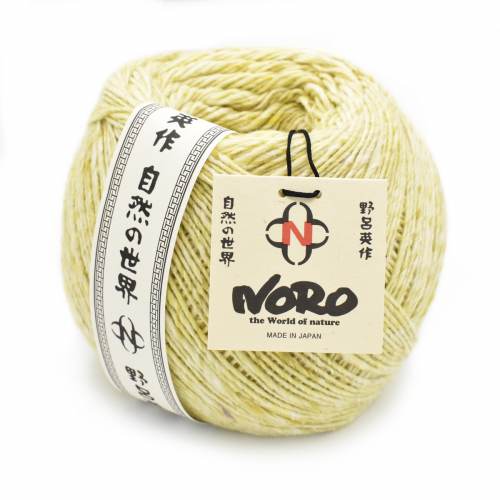

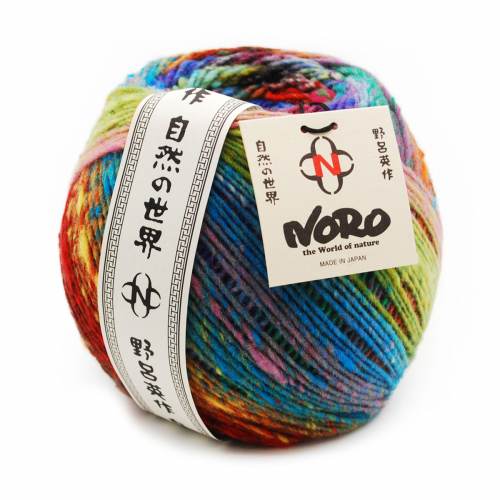

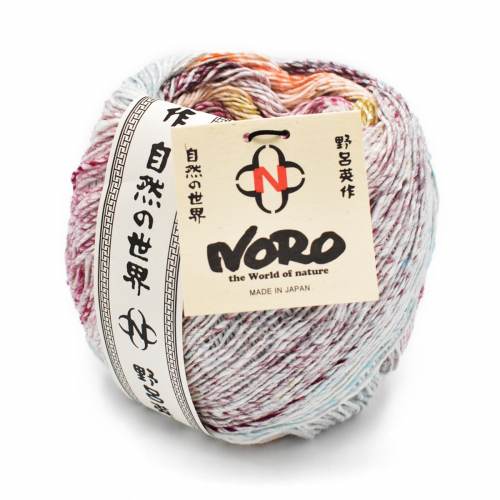

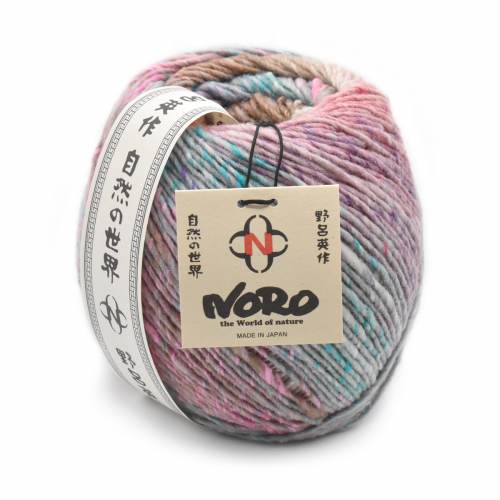

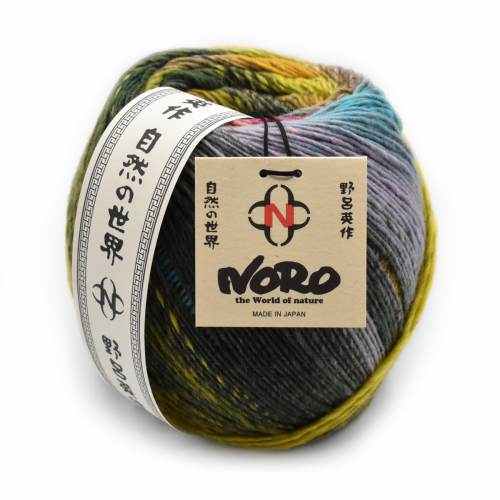

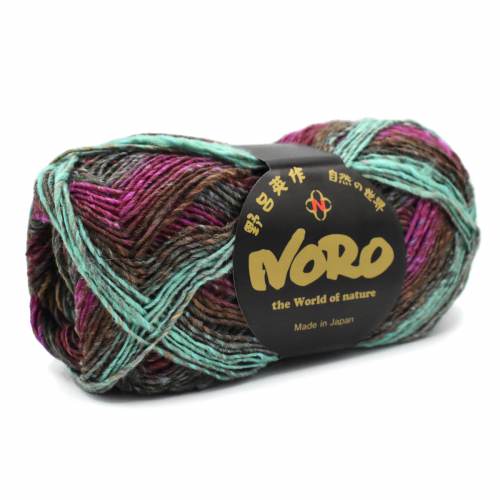

That inspiration is found everywhere in Noro yarns. Take, for example, the colors. Examine a yarn like perennial favorite Kureyon and you'll see color-ways with the vivid golds and greens of a sunflower patch, muted neutral palettes that mimic the infinite hues of bark, and the striking combinations of crimson, chartreuse and orange that one would see in a meadow of wild-flowers.

Indeed, Noro yarns are known for their vivid hues and unique combinations of colors found in the natural world (think of the red leaves of maples or the cerulean blue of the sky). These colors also tap into the multiplicity of shades found around us. Leaves may appear one shade of green from afar, says Mr. Noro, "but in reality they come in countless variations of green. By mix- ing colors, we can give a more natural feel reminiscent of oceans, mountains, flowers, trees and so on."

Noro's insistence on maintaining the integrity of the dyeing process—taking sufficient time to apply color is crucial—creates these rich, complex hues while reducing ecological impact.

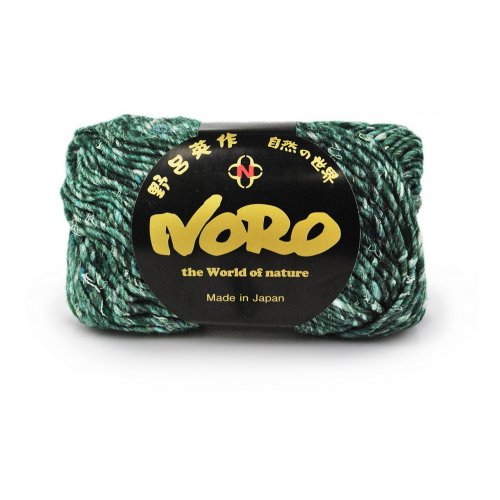

Noro's reliance on natural fibers is another link to the natural world. Chock full of wool, silk, mohair and other fibers drawn from animals and plants, Noro yarns have a visceral connection to the natural world. "Natural fibers have great features that synthetic fibers cannot mimic, and we want to leave these as much as possible in our yarns,"

says Noro. (Think of wool's breathability and the luster of mohair.) The yarn's reliance on natural fibers is enhanced by the careful way that these fibers are gathered.

All animal fibers used to create Noro yarns come from certified organic farms, including producers in Australia, the Falkland Islands and South Africa—the best the world has to offer. Noro himself personally maintains the integrity of the production process, visiting farms, checking the type of equipment used to spin the fiber, and monitoring the dyeing process as well.

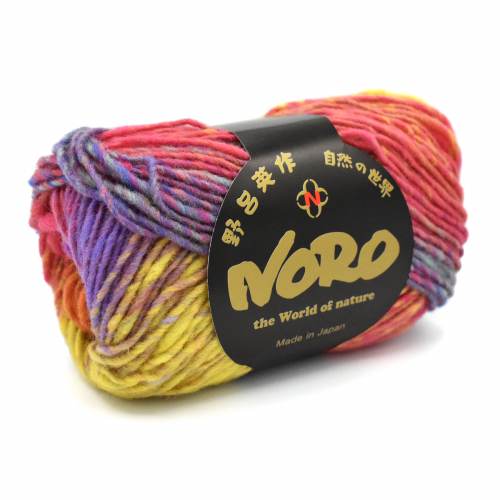

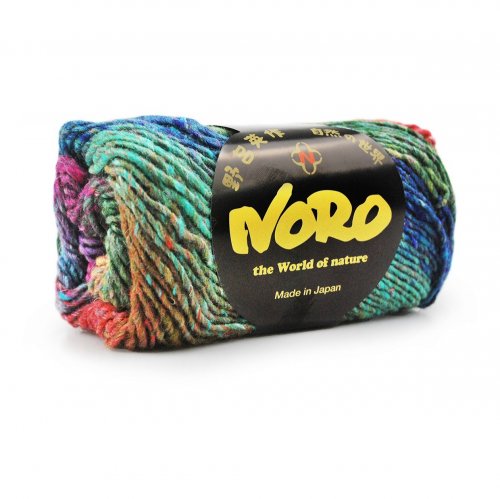

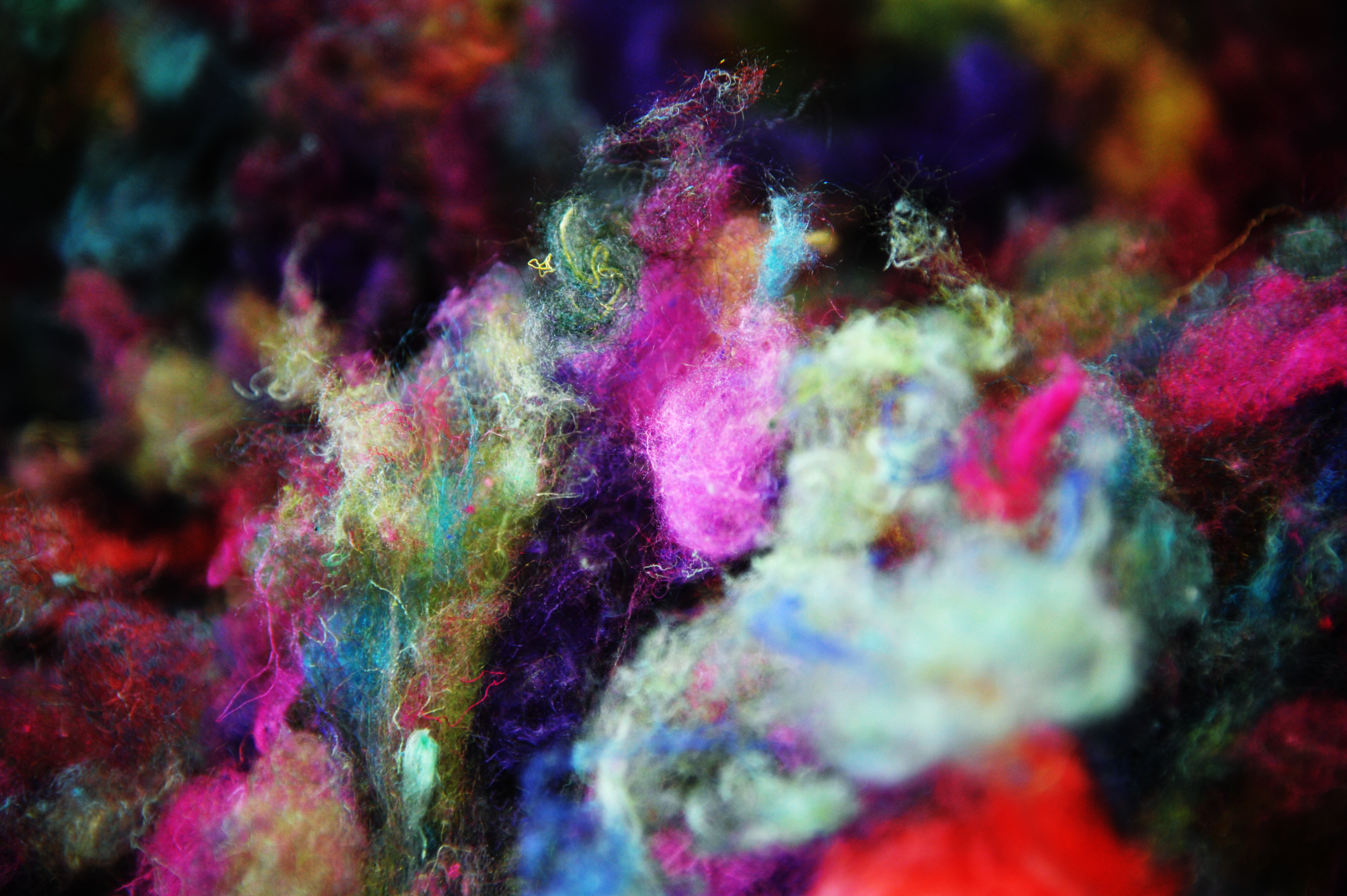

One of the most prominent qualities of Noro yarn is its handspun, loosely processed quality. This, too, is an essential part of Noro's vision of creating yarns that remain true to their natural heritage. Keeping processing to a minimum and eschewing the use of harsh chemical treatments is critical to this vision. Friction created by agitation and heat during processing can weaken natural fibers; by shortening this process, Noro reduces the damage done to fibers and to the environment. Minimizing the amount of machine handling also preserves the original qualities of the fibers. Noro uses only one roller on the carding machine instead of the usual three, uses a shorter bed, and gently hand feeds fiber into the carder. The yarns receive less twist in the spinning process, which creates the variances in thickness along the length of the yarn.

Occasionally, those new to Noro yarns are unfamiliar with their unique texture and unprocessed hand. Don't be put off by these qualities. Variations and slight unevenness in the yarn's texture is not a mistake but rather a deliberate choice so that knitters may feel closer to nature. As Noro observes, "If we make wool yarn, we use various lengths and thicknesses of wool fiber: We want to reproduce the sheep itself in our yarn." Indeed, this willingness to embrace the imperfections and variations is a hallmark of Noro yarns. Eisaku Noro sees this as a cultural phenomenon: "From ancient times, Japanese have accepted, enjoyed and been charmed by the ununiformity, unevenness and occasionally the coarseness of nature. It may be the base of us, and not only the basic philosophy for Noro yarns."